Proven Ways of Waterproofing Roofs

Waterproofing roofs is perhaps the most important factor when it comes to roof construction.

The National Building Regulations and Building Standards Act states that roofs must be designed and constructed safely so that they are not damaged by wind or any other natural force. The law also states that they must be waterproof, specifically:

- Roofs must be durable and must not allow the penetration of rainwater or any other surface water to its interior.

- Roofs must not allow the accumulation of any water on its surface.

But the legislation simply lays down the basics. For additional guidance, anyone building needs to refer to the South African National Standard that explains how the law can be successfully applied.

In terms of waterproofing, the Standard, The application of the National Building Regulations Part L-Roofs specifically covers:

- Roof coverings and waterproofing systems, and

- Drainage and waterproofing of flat roofs.

Roof Coverings and Waterproofing Systems

The SANS elaborates on the legislation stating that roofs must be able to resist penetration of rain to the extent that water in category 1 buildings (see below) any water that penetrates the roof won’t run down the inside face of walls onto the floor, or form damp patches on the ceiling or the floor. In terms of all other buildings (i.e. those that are not category 1), if water penetrates the roof it won’t be intense enough to run down the inside surface of the roof or drip onto the floor or ceiling.

The SANS also state that roof coverings and waterproofing systems must be capable of being repaired if damaged, even if the materials are old.

In addition, roof coverings must be able to resist:

- temperatures from -10 degrees C to +80 degrees C, as well as quick changes of temperature, without deteriorating

- the effect UV radiation, without deterioration

- effects of condensation under the surface

- chemical attack from basic salt or gas in the atmosphere

- growth of bacteria, fungi, lichens and so on

- any penetration or puncturing while the roof is in use

- movement of the roof structure

All products that are used for roof coverings and waterproofing systems must have a lifespan of at least 10 years. If the structure or system is particularly intricate, making it difficult to replace, then the expectation is that materials used should have a lifespan of at least 20 years.

So what is a category 1 building?

Part A: Administration of SANS 10400 classifies all buildings in terms of occupancy (which in terms of the law means “the particular use or the type of use to which a building or portion thereof is normally put or intended to be put”.

A category 1 building falls into various legislated “classes” namely:

- A3 – places of instruction,

- A4 – places of worship,

- F2 – small shops,

- G1 – offices,

- H2 – dormitories where groups of people are accommodated in single rooms,

- H3 – domestic residences that consist of two or more dwelling units on one single site,

- H4 – dwelling houses where there is just one dwelling unit (or house) on the site, and possibly also a garage and domestic outbuildings. This is, of course, your most common “home”.

A category 1 building also has no basements, a floor area that is no larger than 80 square metres, and a maximum length of 6 m between intersecting walls or members that provide lateral support. So you will see that there are quite a lot of South African homes that don’t fall into the 1 category.

Roof Coverings in Pitched Roofs

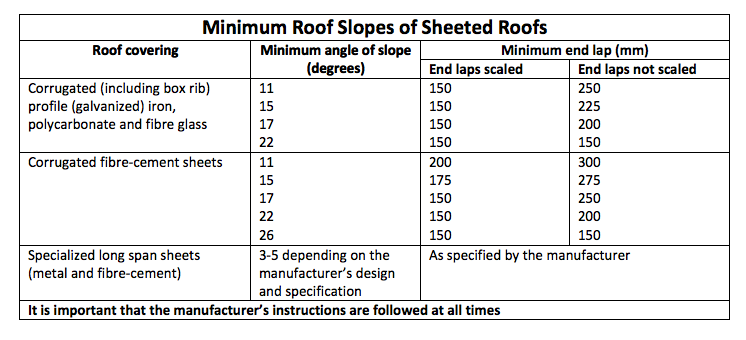

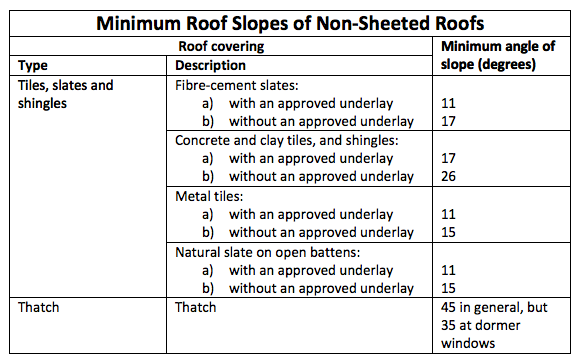

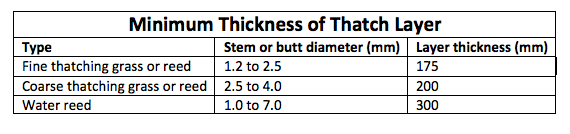

The SANS have useful standards that we have adapted for ease of reference. The three below specify:

- The minimum roof slopes of sheeted roofs

- The minimum roof slopes of non-sheeted roofs

- The minimum thickness of thatch layers

Table 1: The minimum roof slopes of sheeted roofs

If metal roof tiles are used on an existing roof of this category, the existing slope may be retained. But is is important to be aware that if there are strong gusts of wind, the suction force on the roof tiles might exceed the mass of the tiles. If the tiles are securely fixed it will usually prevent them from being lifted. But a much better option is to include an underlay membrane under the slates or tiles. This will reduce the risk of wind uplift because it can lower these pressures substantially.

NOTE: SANS 10062 contains fixing instructions for the fixing of different types of roofing. This national standard is available from the SABS.

The pitch indicated in Tables 1 and 2 are minimums. In addition to these, sheeted roofs in category 1 buildings that don’t have hips and valleys, may have a slope of 5 degrees, as long as all the end laps are sealed and have a lap of at least 250 mm. The slope of any valleys in the roof should then be no less than 11 degrees.

If tiles are laid at a pitch of 30 degrees they must (in terms of the SANS) be tested in a rig as specified in SANS 542. The relative humidity must be maintained at a minimum of 70% during the test, and droplets should not form on the underside of the roof. It is a little different for category 1 buildings – rather than droplets forming (or rather not forming) – the test must show that water doesn’t flow down the inside of the tiles. In other words the roof MUST be waterproof!

Sheeted roofs should be tested in accordance with ASTM E 1646 to check that they don’t leak. There must be no dripping of water onto the ceiling or floor of category 1 buildings.

All tiled and sheeted roof coverings must be installed in accordance with the manufacturer’s instructions and/or by workers with the correct skills.

Thatched roofs should be installed according to SANS 10407. The required thickness of the thatch is shown in Table 3 (above).

All roofs with a pitch less than 26 degrees or more than 45 degrees, and all roofs in coastal areas (to a distance of 30 km from the sea) should have an undertile membrane that is loose-laid so that water can drain between the rafters. If an undertile membrane is properly laid it will provide a very effective, impermeable barrier against wind-driven rain and dust. For this reason the SANS states that underlays should be provided for all slate and tiled roofs, no matter what the pitch (or slope), and where ceilings are not installed.

The manufacturers’ instructions must be followed carefully for tiles, slates and shingles.

Roof Lights

Roof lights have become increasingly popular over the past few decades; but if they are not properly designed and installed, they can leak.

The SANS for roofs state that any roof lights may have an opening of no more than 0.6 square metres. If it is the type that incorporates a translucent roof sheet, it may be 700 mm wide. In addition, roof lights must be able to resist UV degradation for at least 15 years, and hail (at any time) of 10 J (in accordance with SANS 10400-B).

Lastly, all roof lights must be designed and installed in a way that rain will not penetrate the roof.

Drainage and Waterproofing of Flat Roofs

Flat roofs can be extremely difficult to waterproof, which is why all so-called “flat” roofs should be built with a fall of 1:80. This might require a steeper design slope of 1:50 in concrete slabs where construction is not always 100% accurate. A 1:50 slope is also required where there is an interruption in the flow of water on the roof.

The slope should be towards external gutters, roof edges and outlets. Other factors that should be considered include:

- an avoidance of “penetrations” through the roof, or they should be at least 200 mm away from vertical surfaces like walls and “upstand” beams

- an avoidance of having clusters of plumbing pipes, air conditioning pipes, and electrical conduit

- formation of a suitable step between inside and outside areas to prevent water flowing or dripping into the interior of the house or other building

It is very important that precast panels and precast roof structures are designed in a way that if there is subsequent movement of the concrete elements, this will not damage the waterproofing system or compromise its performance.

The SANS has a really useful drawing that shows how construction drawings should clearly designate ridges and valleys, and indicate the relative fall – or slope.

Gutters and Downpipes

Gutters and downpipes are not mandatory. However, unless gutters are designed by a competent person, they may only be located on the “perimeter” of the building. They should also be designed to ensure that stormwater doesn’t penetrate the inside of any building if they become blocked at any stage.

Outlets must be set flush with concrete. If there is timber decking they must be recessed so that there isn’t any ponding around the outlets. Any outlets should be at least 500 mm from upstand elements including parapet walls, and they should be at least one metre from any expansion joints.

Intallation requirements of manufacturers and suppliers of rainwater goods absolutely must be adhered to.

Flat Concrete Roofs

Any concrete roof design should take the thermal properties of concrete into account. This will be determined by a concrete technologist or other competent person, who will determine the required thickness of the concrete and its density, and design the roof in such a way that a waterproofing layer is built up. Often the designer will incorporate a “thermally insulating layer” above the structural concrete deck. When this is done it is important that attention is given to ventilation so that any moist air that might accumulate below the waterproofing layer is vented to the outside.

The concrete used for flat roofs shouldn’t contain more than 7% moisture by weight; and sand-cement or lightweight screeds shouldn’t contain more than 10% moisture by weight.

If expansion joints to accommodate the flow of water are not custom-designed by a competent person, “twin kern upstand-type joints” should be installed over any expansion joints. These should be positioned away from any outlets, and should be built in accordance with the illustration given in SANS 10400-L. Upstand beams that are at least 170 mm high should be incorporated where masonry walls meet the concrete surface of the roof. At these “intersections” (i.e. where they join) corner fillets measuring at least 75 mm (vertically and horizontally) should be build in. There is another drawing in the SANS that shows how this should be done. Another drawing shows how drips should be incorporated under all overhangs of concrete roofs.

In addition to these design elements, all concrete and screened roof surfaces must be waterproofed and constructed to the correct falls and cross falls (see first paragraph under Drainage and Waterproofing of Flat Roofs above and the relevant section in the SANS). It is vital that there are no undulations in the concrete surface, and nothing should be allowed to protrude into the concrete or contaminate it.

The recommended finish for concrete roofs is wood floating. While the final surface should be sound and smooth, concrete and screened surfaces should not be highly polished. So they should NOT be power floated.

Waterproofing Systems

Any waterproofing system that is installed on flat roofs MUST be done by a “competent person” who MUST follow the manufacturer’s instructions. SANS 10400-L states that for roofs to be up to standard, they must remain watertight for at least five years without the need for any form of maintenance other than the normal cleaning of downpipes, gutters and so on. It is also important that the person doing the installation is satisfied that the materials used are appropriate for that particular application, and should therefore take into account:

- the degree of exposure the waterproofing system will be subjected to

- how much protection the waterproofing material will have

- and ultimately whatever affects the building because of where it is located

It is important to realize that waterproofing systems can delaminate if the substrates don’t allow any moisture vapor that has been trapped to escape. Generally a sand-cement screed that is not very dense will allow retained moisture vapor to dissipate and therefore protect against the possibility of delamination.

SANS 10400-L suggests that a 20 mm screed is laid over all “lightweight” screeds, because these are generally too friable and porous to provide good adhesion for waterproofing systems. The SANS also suggests that concrete and screened roof surfaces be allowed to dry thoroughly before any type of waterproofing system is applied.

Where waterproofing turnups are provided against brickwork and other masonry walls, they should be counter-flashed if they are not linked to the stepped damp-proof courses in cavity walls. The same membrane should be used, and the flashing should be cut into walls to a depth of at least 40 mm.

Generally sand-cement coves with a radius of at least 45 mm should be formed at all the inside corners of both vertical and horizontal surfaces – unless a particular waterproofing system has a different design and doesn’t require this. Where there is a timber deck, 38 mm timber fillets may be fixed at all the junctions of horizontal and vertical surfaces.

There is always a potential problem with outlets. The installer must therefore pay close attention to overflow pipes, flues and so on, and make sure that the waterproofing material used covers everything but the opening. Generally waterproofing membranes around any pipe work should be clamped with a hose clamp or something similar, before flashing is applied over the pipe.

If outlets aren’t the “full-bore”, coned type, pipes should be flanged so that waterproofing can be done correctly. Elements such as water storage tanks and solar absorbers should never be allowed to penetrate the waterproof layer.

All external corners and edges to be waterproofed should be rounded, and the height of all DPCs should be at the same level as the waterproofing turnups.

In addition to this part of SANS 10400, SANS 10021 also provides some information and guidance about the waterproofing of roofs. Remember, it’s important to do it correctly!

SANS10400-Building Regulations South Africa SANS10400 are the Building regulations in South Africa, and both international and national standards, are fundamental to successful building and construction projects, both big and small.

SANS10400-Building Regulations South Africa SANS10400 are the Building regulations in South Africa, and both international and national standards, are fundamental to successful building and construction projects, both big and small.

hi i hope you can assist me . in 2002 we added a guest room to our

house . recently we found out that leaking was not due to shoddy

waterproofing work but the gutter was higher than the roof, so the

water cannot drain properly. waiting to hear from you . thanks rike

I’m building a granny flat for my gran on top of my garage. I live in

a 3 bedroom house in Durban North. Somebody told me that its a law

that i must provide parking for the granny flat regardless of whether

or not the occupant is a granny who cant drive. I’m trying to avoid

this as i will need to dig back a bank and create a huge expensive

retaining wall. What are the rules for parking?

Hi. I purchased a house 2 years ago and now the roof is leaking

terribly. I have collected the building plans from the municipality

and alterations were made to the house prior to my purchase. How do I

find the building inspector that verified that the alterations were

done according to building regulations. The ceiling has caved in from

what appears to be incorrect roof alterations. Gutter inside the roof.

Can you please assist? Thanks Jaco

Hi Jaco,

Sorry to hear about your problem. I am not sure what part of the country you are but I suggest that you contact the local municipality where you got the plans from and ask them to tell who the inspector was and ask them why the roof alterations were passed by them. The other choice, depending on the amount of damage and the cost to repair it, would be to get a qualified Independent Building Inspector to give you a report and he should be able to tell you if you have a claim and against whom. Is there a signature and an “approved” or “Passed” stamp on the copy of the plans? This should tell you who signed them off and when, this is also important when it comes to normal deterioration and wear and tear over time. Let us know what the outcome is.

Hi Rike,

Eleven years is quite a long time to discover the cause of your leaking problem. If you are asking whether you have a claim against the contractor I think you will find that it will be way past any legal time limit (prescription) to take any legal action. I am sure you can get a decent “handyman” with references in your area that could handle the job of re-positioning the gutters.

Hi, kindly advise on the following major problem.

A developer has not waterproofed the post-tension concrete slab which forms the roof of a basement parking, the telkom room, the electricity meter room, building supervisor’s offices and store room resulting in serious water leaks between the unbonded slabs and cracks that have formed due to the slab being exposed to (the elements) UV radiation and thermal expansion and contraction. Kindly advise on the legal requirements prescibed for developers regarding waterproofing the post-tension concrete slab which forms the roof of a basement as described above. Thank you. kind regards. Roy

Currently I have Brosley tiles on the roof and as they are no longer avaiable and due to contractor applying TAL Bond , SBR latex to the roof as a primer, I now have to replace the whole roof.

What are the requiremenst, do I need council approval – Guateng- and who can guide me to ensure that the correct selection of roof tile and fitting of roof tiles etc.Are there professionals that can ensure that the project is done according to the required regulations.

Thanks

Charl you simply need to use SABS approved tiles. The manufacturer should be able to give you detailed information regarding how the tiles are fitted. They may also know of professional contractors who have experience working with their products. We are not able to recommend products specifically. Your local council might be able to recommend products, but be careful…

how do you see the place that need water proofing on the corigated iron and how to solve the problem ,tell me step by step

You’ll know if it’s leaking. There should be a plastic underlay to stop any leaks.

Hi Roy,

These seem to be problems that the local building inspector should have picked up before occupation/completion certificates were issued. You then have recourse to them to instruct the developer/builder to rectify the problem. Waterproofing is covered in SANS 10021(2012): The waterproofing of buildings (including damp-proofing and vapour barrier installation). There are several pages in the Standard that relate to waterproofing requirements for basements and semi-basements. I suggest you purchase a copy or go to your nearest SABS library and read it there. You might need to get an independent assessor involved to give you a full report. This will add to your case if this escalates to court.

WE purchased a house in a complex that was built by one of the nominated contractors. We took ownership in June 2008. There is a 5 year latent defect clause. The flat roof has been leaking every year despite cleaning the gutters. The contractor in question has been back several times patching up.

As it will be 5 years up in June this year, do we have any claim to ask the contractor to repair the roof properly, so that there are no more leaks. OR do we pay for another contractor to come and sort it out? Many thanks

Ann, I am not sure where you live – but where I am we are into the rainy season and so leaks are going to be very evident in the next few months. You could put him to terms in writing detailing the history and stating that should the leaks recur he will be liable to pay for the job to be done correctly. But this would probably need to be done through a lawyer – otherwise you’re probably not going to get your money back even if the problem recurs before June. It might be better to call in two or three other contractors and ask for detailed quotations – so you can see what work they believe should be down – and then demand that the person who built the house fixes it. And/or contact the NHBRC because their warranty scheme covers leaks for five years – and let them fight with the contractor. Since this is a “nominated contractor” if he isn’t a member of the NHBRC there will be big trouble for the developers.

I live in Cape Town. and many thanks for the advise. Will update you.

Trevor you will need to submit plans for a granny flat – and if parking is required, the local authority will tell you to add it. Parking rules are set by the local authority, so they are the folks you need to talk to. It isn’t something that is laid down in the national building regulations.

I have seen gutters are no longer a requirement but seems still a needed….kindly advise on your findings on gutters and why it is perhaps a good thing

Gutters and downpipes are the most usual way we channel rainwater away from buildings, but outlets may also be used. Sometimes architects use chain (or something similar) instead of downpipes, to form an element that the rain can run down. It can be effective and looks quite quirky. I’ve added a picture to this page.

According to SANS 10400: Part L Roofs, if outlets are used instead of gutters, these should be set flush with concrete or recessed into timber decking (depending on the structure) to prevent ponding. Part L of the Standard also states that “the position of all outlets shall be at least 500 mm away from upstands, parapet walls and 1 000 mm away from expansion joints”.

Great blog here! Also your website loads up very fast! What web host are you using?

Can I get your affiliate link to your host? I wish my site loaded up as fast as

yours lol

Thanks for the compliments. Our web host is just-hosted.com – they have an ad on our landing page. Based in the USA. Highly recommended.

What tipe of material is allowed to seal ridging on an existing roof?

Is “pap & lap” still allowed?

Hi Mariana,

As far as I know “pap ‘n lap” has never been disallowed. The thing is that there have been technical advances in waterproofing products that will now last a lot longer. You do not want to redo the job every season. Just ask your local hardware store what they recommend.

Hi,

Can anyone please indicate the minimum crown coverage when using sheet roofing and Nutec barge boards or point me to a SANS code?

Thanks

Gerhard there is some information on the general roofing pagecap on this site. However this Part of SANS 10400 does not mention the words “cap” or “crown”. Other standards discuss the materials and fittings used, but I don’t think will answer your question. I suggest you contact Everite for advice. I have given you the link. They briefly discuss design criteria on their website, and state that “Site service personnel are available on request and at no charge, to provide assistance on recommended storage, handling and erection of the Company’s products.”. Here’s a link to all their contact numbers country wide.

Hi Penny, much appreciated. I have spoken to Everite and have their letter confirming that using their product 260 x 260 barge board over a 0.762 Wide Deck profile and covering only one ridge/crown will suffice. However, the local authorities still insist on a coverage of at least two ridges/crowns. It is strange that the NHBRC has no detail on this.

Gerhard have you contacted the NHBRC? I have looked at their manuals and don’t see anything – but maybe someone there can advise you further. I would object based on the manufacturers guidelines. The legislation does give you the right to object. And in any case you are not non-compliant in terms of the NBR. I would ask them what they are basing their demands on.

Water came through my roof into a room in my house. The builder says

it is not a latent defect. I would like to discuss this issue to get a

better understanding of what latent defects are and responsibility of

the builder.

Lorraine, is this a house that you had built, or one that you bought? Essentially a latent defect is a defect in something that has been purchased that is not apparent after ordinary inspection by a “reasonable” person. A patent defect, on the other hand, is something that someone would notice. So if, for example, bad workmanship was the cause of a leak (perhaps no underlay in the roof), but there was no way you could have discovered this, then it IS a latent defect. Generally when purchasing a house, if the seller knew that there was something defective and didn’t disclose it to the seller (e.g. the roof leaked and the seller did not disclose this) then it is a latent defect.

My gutters drain into my neighbours yard as the angle of my roof is towards his hom. The gutter is about 20 m from his front door and drains into his garden. He is unhappy with the situation and threw bricks on my roof and blocking the gutters resulting in damage to my electrical equiment under my roof. Please advise on the proper procedures for gutters and the place where they may drain

Gerhard, first of all your neighbour may have a legitimate gripe (I would be very unhappy if I was in his position), but he is totally out of line throwing bricks onto your roof. What I would have done was take photographs and then get a professional to assess the damage – and bill him for it.

In terms of the correct way to affix gutters and downpipes, you need a professional, registered plumber to do this for you.

Hi,

Are there regulations limiting the directing of storm water from the roof into the municipal waste water drains (where toilet and shower water goes)?

The back of our plot is walled on three sides and water dams up after heavy rain. Could I allow the rain water to drain into the sewage system to solve this problem?

Thanks

Albi

We want to rebuild a house that burned down. The outer walls are still intact but we are thinking of building the roof on metal columns of 100 x 100mm, 2,4 meters apart. Is this allowed?

Secondly what is the minimum angle for a flat roof? It is 8m to the drop side and 25 meters long. Is 7,5 degrees allowed?

Current am experiencing a leak through the valley area whch apparently is in correctly installed.latent defect.Can I just place “pap & lap”over the valleyThis means that no water will go into th evalley but will flow over the “pap & lap”into gutter.

Hi Wins, without seeing exactly what you are referring to, yes you can do this but I will suggest you use a modern type of “pap & lap”, and seal the edges so the water does not seep under the edges, so that it lasts as long as possible. There is a product called “Flash Harry” that you might have a look at that might suit the job. Phone them for advice, Contact: Darachem (011) 892-2917, (011) 917-9816

You are going to have to submit plans to the local authority; they will advise whether you may do this or not.

Albi the plumbing regulations are quite strict; and there are quite a few of them. SANS 10400 Part R deals with stormwater drainage in particular.

First of all you may not channel stormwater into any type of drainage system. BUT all stormwater must be efficiently disposed of; and all ground levels, invert levels, sizes and grades of pipes and channels must be shown on the drawings submitted to council. Perhaps more importantly, the final disposal of stormwater from a site must be clearly defined and must be designed in consultation with the Local Authority where necessary.

I hope this helps.

Hi

We bought a house July last year (moved in). The house is a flat concrete roof but the roof has no slope.

From the inside of the house you can see they used long thing ‘beams’ of concrete that seem interlocked. They have been cemented over but you can still see their profile.

I am struggling with this roof immensely as it leaks everywhere, and water pools up on the top.

We have tried applying the torch on bitumen rolls, doing it ourselves, but it only lasted maybe 3 rain showers and the leaks popped up everywhere again. I have thought about tiling the roof with porcelain tiles but i see that they too are not 100% waterproof.

I don’t know what to do…

George my suggestion would be to remove all the bitumen and get a plasterer to lay a screed over the top of the roof to create the required run-off – at least 1:50 as specified in the regulations. If they use a waterproofing compound in the mix it will help, and then you could paint the surface with a good quality bitumen compound.

Flat roofs cannot be tiled – and for the record I think you mean clay, concrete or slate tiles. Porcelain is way to fragile to use for roof tiles.

Good day,

We have a problem with water seeping through a flat concrete roof in one room only.. I asked the builder to remove a 1m wide strip of the bitumen/tar that was used. On doing so, he found a crack which I saw on camera. I do not know if this crack is structural. (I am a woman and find it difficult to climb up the 1st floor to see myself so I rely on his pictures.) There is a product I discovered called MattCrete used for waterproofing. I used thid product with a polyethylene membrane to close down the opened strip. Would you recommend this product for the rest of the roof? If not how do I solve this problem.

Best regards

Dimakatso Motsepe

Good day, I recently bought a house with a slate roof. It has an underlay and the tiles are lined up next to each other, so the underlay does all the waterproofing.

Shortly after we moved in last year the roof started leaking in several places. From my inspection it seems the underlay is at the end of its life. Apparently it only lasts about 5 to 6 years.

From the comments of contractors I’ve received it seems the slope of the roof is too low, although it doesn’t leak everywhere and the slope is low there also.

Two questions, where can I find more information on the types of underlay used for slate roofs and their life span? And, if the roof doesn’t comply with the regulations, do I have any recourse on the previous owner or estate agent who sold me the house?

Thanks,

The first question is what kind of underlay was used? Was it an SABS approved product and was it installed correctly?

When you say roof underlay only lasts 5-6 years, I am guessing that you Googled “roof underlay” and read some US data. Houses in the USA are not made to last – that’s a fact. I don’t know their specifications for roof underlay, but they are not the same as the SANS for products in SA. In current building practice, the undertile membrane has become an integral part of any tiled roof (slate, clay or concrete). When it is laid properly, it will provide a highly effective barrier against the ingress of wind-driven rain and dust. The pressures exerted by wind forces will also be substantially reduced due to pressure equalisation, greatly reducing the risk of wind uplift. BUT, the material used must meet SABS specifications.

The most common roof underlay is a simple yellow or white damp-proof course (the link given will take you to the Gundle site) – This is specifically “a polyethylene membrane that has been specially formulated for use under roof tiles. It is supplied in rolls of 1,5 x 30m and is dimensionally stable, light in weight, translucent and weatherproof; handling and installation is easy.” And it has a life expectancy of 25 years! Not 5 or 6!!! Gundle also makes a woven tile underlay (that has an agrement certificate) and lasts even longer. So if yours is deteriorating, it is probably a sub-standard product.

In terms of pitch, if you go to this page, there is lots of useful information from the NBR.

In terms of recourse, you would only have recourse if you can prove that this is a latent defect that the previous owner was aware of.

Dimakatso, unfortunately I don’t know the product and would, in any case be loath to recommend anything that I really knew worked well. If there is a crack it should be filled with a cementitious product or some sort of filler foam. If it is a structural crack it should be pinned. Only once this has been done should you waterproof it further. Bitumen is good and there are many other waterproofing products. I just can’t hazard a guess as to which is best.

Hi Penny,

I have a very similar problem on my roof. The sheeting under our tiles are some kind of a Membrane…. This membrane from the looks of it was never pulled over to the end during the initial installation….now when it rains, water builds up in our ceiling and when this bubble is getting to heavy in the roof, it pops and water rushes down our walls, through the ceiling or anywhere were gravity takes it.

My question, should this membrane not be pulled right over the last row of brick work and be visible when looking at the roof from below?

Andries

Andries it may be that the tiles were not laid correctly and because of this water is leaking in and stretching the membrane. The NBR doesn’t have step-by-step instructions on how to fix the DPC, but obviously if there are gaps under the tiles – which would happen if it wasn’t stretched other over the brickwork or right to the edge of the wall – it won’t be fulfilling its function and will be compromised when it rains heavily. I’m not sure if it should be visible (I would prefer it not to be, from an aesthetic perspective) but I guess it normally is.

Hello. We bought a unit in a sectional title block in 2008. I personally started occupying the unit in 2011. I noticed that the flat concrete roof cracked terribly at night. Some time after that I also noticed serious cracks appearing. I called out an engineer to do an inspection. He confirmed that the developer never installed an expansion joint in the roof. It is now 2014 and the developer still denies that he is responsible to remedy the situation. The engineer estimates the fix to cost around R2m. We started legal proceedings against the developer last year. But his attorneys are adamant that the roof does not need an expansion joint by law. Is this true? Thank you.

Wouter, the Building Regulations were updated in 2008 and the Act states:

The roof of any building shall be so designed and constructed that it –

(a) safely sustains any actions which can reasonably be expected to occur and in such a manner that any local damage (including cracking) or deformation do not compromise its functioning;

(b) is adequately anchored against wind uplift;

(c) is durable and does not allow the penetration of rainwater or any other surface water

to its interior;

(d) does not allow the accumulation of any water upon its surface; and

(e) as part of a roof and ceiling assembly, provides adequate height in any room immediately below such assembly.”

To be able to satisfy these legal criteria, it is essential that expansion joints are incorporated – even though this was not previously spelled out in the SABS “deemed to satisfy” rules.

Prior to this the law was less definitive – as I explain on this page, Roofs.

However the deemed to satisfy (dts) rules (1990) state that roofs should be “the subject of a rational design in accordance with the requirements contained in Parts B and C and such roof … complies with” other dts rules. B = structural design (Unfortunately I don’t have a copy) and C = dimensions. So even though the 1990 dts rules do not state (as the new ones do) that expansion joints are essential, there should have been a rational design (probably by an engineer) PLUS good building practice should have been followed – which it clearly wasn’t. I say this because he is probably going to claim that he built the homes in accordance with the old regulations. I guess this was a problem, which is why the whole Part L, Roofs (of SANS 10400) is much more detailed.

The new (2011) SANS – which are the new dts regs – state:

“4.3.3 Flat concrete roofs

4.3.3.1 Unless the expansion joints are designed by a competent person (built environment) to accommodate the flow of water over such joints, twin kerb upstand-type joints (see figure 3) shall be installed over expansion joints in concrete roofs, which shall be located away from outlets.”

Thank you Penny. You help is much appreciated. This roof is ripping the building apart especially in my bedroom where next week the one wall is being broken out and rebuilt because the movement of the roof caused the 2 lintels above my bedroom door to break and pull apart. I keep on spending so much money (so does other BC members) just to try and keep the cracks (some up to 5mm in width) under control. Would the developer be liable to remedy for such a huge structural defect? Does the voetstoots clause protect him for such severe structural defects that is causing problems on an ongoing basis?

Wouter, Unfortunately you are out of time in terms of the NHBRC 5-year warranty plan, however I have absolutely no doubt that the developer is liable. But you are going to have to get an attorney to represent you. In terms of the voetsoots clause, I believe that there are times when it may be considered null and void, and I guess this would be one of them. How can a developer expect to be protected when his workmanship is defective? Unfortunately this type of thing happens far to often, and I personally do not believe that the NHBRC is playing a meaningful role. If I were you I would take photographs now, when the work is done next week, and afterwards. You might need it for evidence if the case goes to court.

Hi Penny. I noticed during construction that the developer did not install under tile membrane. I thought that this is a standard feature on all Tile roofing. The developer says it is a added extra and I should have told him if I wanted the membrane to be laid. Am I being cheated here? What are my options?

CM this is what the National Building Regulations state:

“4.2.2.6 Undertile membranes shall be laid loose so that water can drain between rafters and shall be installed strictly in accordance with the manufacturer’s instructions where tiles, slates and shingles are laid

a) in roofs that have a pitch of less than 26°, or

b) in roofs that have a pitch of 45° or steeper, and

c) in those areas between the coastline and an imaginary line 30 km inland, parallel with the coastline, or the top of the escarpment or watershed of the first mountain range inland, if these are less than 30 km from the coastline.”

So if the pitch of your roof is less than 26 degrees or more that 45 degrees, or you live at the coast, then it MUST be included as a standard feature. i.e. It would not be optional. If you live inland and the pitch is between 26 and 45 degrees, then it would be an added extra.

Thanks for your advice Penny. Very useful. God bless you..!

Hi, I just would like to know if it is mandatory for me to put in the undertile membrane if am using the HARVEY TILES for roofing, my roof pitch is more than 26 degrees, and am inland? Thank u in advance.

If you look at the first comment on this page you will see that I have already supplied this information. Thanks.

Hi

We have a lot of waterproofing issues

our house was built 2 years ago – we bought directly from developer

after all the rain in summer season, we saw that the garage and balcony hasnt been waterproofed sufficiently

the walls beneath the balcony (our patio) looks terrible of water marks and paint coming off

we’ve been struggling for months now for the developer to fix this and frankly they’re just ignoring us

what I want to know is, is there something we can do legally or a building regulator that we can report them or something? just to help us fix this

Thank you

Charmaine

Check with the NHBRC to see if the developer is registered – he should be and the house should have been enrolled and inspected by the NHBRC. If he isn’t he is building illegally. Either way – report him to the NHBRC. If this is causing major structural damage then you should still be covered by the NHBRC’s 5 year warranty (if of course the house was enrolled). You could also report him to the Master Builder’s Association. Alternatively you will need to go to a letter to send a letter of demand that he fixes the problems within a specified period of time.

Thank you very much for the prompt reply!

We will definitely use the advice

Hi

Is Multiwall Polycarbonate sheeting allowed for roof sheeting?

Generically polycarbonate sheeting is allowed for roof sheeting. It isn’t clear from the Multiwall website whether or not this specific product is SABS approved. You will need to check this with them.

Does anyone know of an Engineer that can do a report and recommendations on waterproofing that I can get implemented and claim back from the builders?

Stefan we aren’t currently in a position to recommend practitioners. Try the Master Builders’ Association

I am looking at starting a paint contracting business and found this article while searching for information on the subject. I see that accreditation will soon become law and that SAPMA is the only institution that offers training in the field. They do not seem to include waterproofing in their modules though. My question is thus: where does one receive training in damp and waterproofing techniques? I would also like to know if there are other institutions you may know of that provide training for prospective wall and roof coating practitioners.

Thank you

The best is to ask one of the professional waterproofing manufacturing companies such as Duram, as it would be in their interests to give or to know where to go for training.

Hi there

i have a building with a concrete roof. the cocnrete was used as i intended on building a 2nd floor, however these plans have now been abandoned.

i have however run in to some problems

1) water leaks through the concrete slab

2) water leaks into the building along the external walls into the walls.

will waterproofing using membrane and torch on solve these problems.

i would also like to know

what is the regulation regarding commercial buildings with regards to concrete roofs:

is it possible for me to build a roof over the concrete slab as this will easily and more effectively solve the problems instead of constantly using torch on to waterproof

This will certainly solve the problem of continuous water-proofing. Contact one of the many roof truss manufacturers and ask them to advise you on the best design for the water runoff and the best way to fix it to the existing structure. They have all the qualified people that will supply you with COCs to give the council when you give them your amended plans, most times this is a service they give free as part of the truss manufacture.

Hi, is the December month the right time to install the Roof?

I am not sure what you mean, you do not say where you live. The best time is when the roof trusses have been put up and the roof is ready to go on.

We are purchasing a house and upon Inspection it has been discovered that there is no under tile membrane, which is required as the roof is below 26 deg. Is the seller allowed to sell the house if it does not adhere to the bulding regulations? is there any other waterproofing system that should be used to adhere to the regulations?

Yes the owner can sell a house if it does not adhere to the National Building Regulations – even though this (not installing the membrane) would have been in contravention of the law. If the owner knows about this (they might have been conned by the builder) and tries to hide it from the purchaser, that would be a problem and it would be their responsibility to fix it. However, you could put a clause in your offer to purchase that they must install a membrane. The problem is fixing it with the tiles in place.

Guarantee that pap n lap from valley onto roof covering is not a good idea. Get the problem sorted out properly. pap n lap is hardly ever a good idea unless a very short term disaster solution. It’s the same as trying to fix a hole in exhaust pipe with gun gum and tape. It is a short term cheap and nasty method and has no place in original construction . it seems to be the standard of the day however, but not in europe or usa etc. To ensure a tight seal onto undulations is very difficult and will result in folds some where. Also if you seal across vertical joins the vertical join above it must be sealed to the next cross lap which may be right to the ridge in sheeting . On tiles to underneath the next tile up. Better to make a professional plan for the problem.

Contact WAG – Waterproofing Association Gauteng or DWASA

http://www.wpag.co.za

http://www.dwasa.net

Regards,

Danie

Mpumalanga Rubber

If a body corporate uses a flat roof top as an exclusive use area for entertainment purposes, what is the legislation with regards to the legal height of the parapet wall around that roof?

many thanks

Craig

There is nothing in the NBR that specifies this, though I guess it would fall under the regs that relate to balustrades and safety. However, the parapet wall would need to be on the approved plans and the roof top area would need to be designated ON PLAN as an area that will be used by people.

Hi,

Just wondering if anyone can help. I have paid a builder R140 000 to build me one room added onto my house. The room has got water running down the walls coming out of the floor and seeping through the back wall between the floor and the wall. He says that its not his problem he didnt not quote for waterproofing or drainage.

Surely that is included when you build a rooom. If anyone can help, let me know.

Our house is an old one ( built in the 60’s when they still built them properly!!) and in November 2015 a massive hail storm blocked two valleys and as a result, the roof leaked. I have since been told that since the roof has no underlay, it will not be covered by insurance. Its the first time its ever leaked, so we had no idea that there was no underlay. The pitch of the roof is quite steep, definitely steeper than most rooves – my husband is 6 ft and he can walk in the ceiling with clearance. Aside from that though, should we now investigate underlay as well as redoing the valleys and ridges? We were going to “waterproof” the whole roof without underlay but do we now need to underlay as well?? Really not looking forward to the added expense if its not necessary!

I bought my house in 2012 and my roof is leaking now in 2016. When the bank sent their assessor out they said my roof pitch is to flat on my patio and I need to get an engineer to give me a certificate and I must fix the roof my self. My question is how did my bond get approved originally but now when there is a problem they say it is for me to fix. What can I do has they now say even if I want to increase my bond I can not until a engineer approves my roof. Please help I don’t know what to do. What is the cost of an engineer.

Unfortunately the reality is that banks don’t generally do proper checks before they approve bonds! You will have to find an engineer and see what he or she charges. I have no idea.

You should sue him … that is ludicrous! All building work must be done according to the NBR and this includes the need for DPC under floors and under walls.

Not all roofs require underlay. Check this section to see if you can ascertain whether your roof does – partly to do with the pitch.

In addition, the regs suggest: “An undertile membrane, when properly laid, will provide a highly effective impermeable barrier against the ingress of wind-driven rain and dust. Underlays should therefore be provided on all tiled and slated roofs, irrespective of the slope and also if ceilings are not installed, so as to minimize the effect of wind-blown dust entering through the tiles.”

I can’t find the reference, but I think there is something about underlay being required at the coast. I might be wrong.

However if yours is an old house, I would argue that unless the insurance policy specified that there must be underlay or that the roof must comply with the new NBR, then they need to cover the damage.

Hi,

Just bought a town house and moved in beginning of June 2016. The place was build in 2013 but the roof is leaking. I was told by a friend that the water proofing must have a 5 years guarantee and I have just read above the requirement of the SANS 10400-L and it states that the “Roofs to be up to standard, they must remain water tight for at least five years”. Does this mean I can request the developer to correct the leaking roof?

Your assistance will be much appreciated.

Since you are not the original owner, any guarantee will not be in your name – though it should be transferable. The other question is whether the builder was compliant and gave a guarantee of any kind. Whoever built the town house should have been a member of the NHBRC and the dwelling should have been enrolled with the NHBRC. This would give you access to the standard NHBRC warranty. But as you quite rightly say, the NBR require the roof to remain water tight for at least five years … so clearly the developer/builder is liable.

Do you guys offer waterproofing training

No we don’t offer any form of training.