Concrete Mixes & Batch Ratios

For Different Applications

The basic techniques that will enable you to cast a foundation or slab are relatively straightforward. The secret to success lies largely in the correct quantities being mixed together in the concrete mixes you use. Although the principles of mixing concrete and mortar are simple, this can be backbreaking work, especially if you decide to mix the concrete by hand yourself. If there is a reasonably large quantity of concrete to be used, it is advisable to hire a concrete mixer. Whether you are mixing by hand or in a concrete mixer, you will have to measure materials accurately to ensure you achieve concrete of consistent quality.

Batching Generally, materials for smaller jobs are batched by volume. Recommended ratios will enable you to mix concrete to match the function for which it is intended, or the strength of the concrete required.

One 50 kg sack of cement has a volume of 33 litres (0,033 cu m). A builders’ wheelbarrow, filled level to the top, has a volume of 65 litres (0.065 cu m, which is almost double the volume of a sack). When batching by volume, it is safe to assume that one wheelbarrow-load is equivalent to two sacks of cement. Since sand bulks in volume when it is damp, the mix ratio table (below) is based on the use of damp bulked sand. If you are measuring dry sand, reduce the quantity of each batch by 20–25 percent. You will also need to add more water to compensate for the lack of water in the sand. The recommended ratios are based on the use of either 19 mm or 13,2 mm commercial crushed concrete stone. Stone does not bulk in volume when it gets wet and so no correction is necessary.

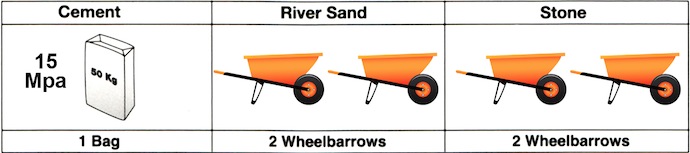

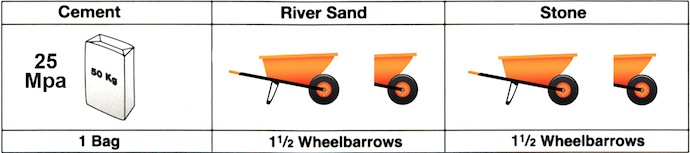

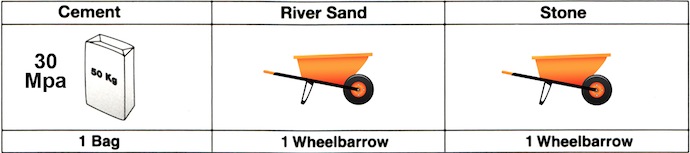

Large Batches of Concrete Mixes

15 Mpa This is a low-strength concrete mix and is suitable for house foundations that are not reinforced, and for boundary walls and freestanding retaining walls.

25 Mpa This is a medium strength concrete and is suitable for reinforced foundations, light-duty house floors, patio slabs, footpaths, steps, driveways and garage floors.

30 Mpa This is a high strength concrete and is suitable for suspended structural beams, pre-cast beams and flagstones, heavy-duty workshop floors and suspended reinforced floors.

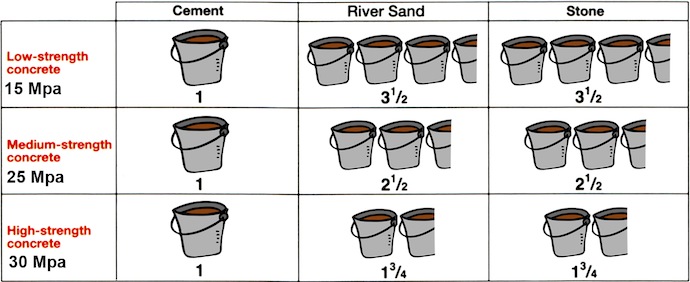

Small Batches of Concrete Mixes

You can use containers such as buckets, drums or tins. It is important that the same size container is used for all materials in a batch.

Moving and placing the concrete

Concrete Mixer

Note the reinforcing and the plastic waterproofing underlay.

Ready-Mixed Concrete

If you have large quantities of concrete to place, it is much more convenient to order it ready mixed. It is then mixed in a factory environment, according to your specifications. You must just ensure that workers are on site to place the concrete as soon as it is poured from the truck.

SANS10400-Building Regulations South Africa SANS10400 are the Building regulations in South Africa, and both international and national standards, are fundamental to successful building and construction projects, both big and small.

SANS10400-Building Regulations South Africa SANS10400 are the Building regulations in South Africa, and both international and national standards, are fundamental to successful building and construction projects, both big and small.

GOOD ARTICLE, IT CAME TIMELY. I HAVE SEARCHING FOR ANSWERS ON CORRECT RATIO FOR CONCRETE MIXES, YOUR ARTICLE GAVE ME THE EXACT ANSWER I NEEDED.

Thank you for the clear information tou put inthis article. It’s helpful.

Why fc’ is Only 15, 25 & 30 Mpa???..

How if I want to know the fc’ of 1Cement:2Sand:3Gravel ?

How can I calculate the fc’ ?..

Or vice versa , I want to produce fc’ =21Mpa, how can i calculate the concrete mix?

thanks..

Surely you have a text book. We do not do students homework for them.Fulton’s concrete technology is an excellent resource.

Hi. Where can I find the minimum required strength for a building block? Thank you for an excellent website.

Hannes, this link will take you to our downloads page. Scroll down and you will find a link to How To Make Concrete Bricks and Blocks. This is a very useful little publication that was produced by the now defunct Cement & Concrete Institute. The Concrete Masonry Manual – link on this same page – also has specifications for building blocks.

Thank you Penny it helps a lot.

Has another body took over C&C institude? Plse email me hannesrichard@gmail.com

Hannes, from their old website I see that a new non-profit organization has been formed.”The new company will be funded by AfriSam, Lafarge, and Sephaku and will begin operations on Thursday 2 May 2013.”

From what I read at the time, they closed because their main sponsor, AfriSam withdrew their funding. Looks to me like it’s got to do with BEE and suchlike! But I really don’t know.

Hi Hannes,

They are now called “The Concrete Institute”. Here is a link: http://www.cnci.org.za/EN/Content/Home

Hi, I am looking for the ratio by weight of cement to a premix of sand and stone (already combined) to produce 40MPa concrete.

Thanx

Hi Peter,

You will have to figure out what the ratio of sand to stone is in your premix and also gauge/guess what size the stone is.

Here are the trial mixes for 40MPa from the Cement and Concrete Institute handbook:

Stone size 13,2mm Mass/bag———–Cement= 50Kg—-Sand= 68Kg—-Stone= 68Kg

Mass/Cubic Meter—Cement= 575Kg—Sand= 780Kg—Stone= 770Kg

Stone size 19,0mm Mass/bag—–Cement= 50Kg—Sand= 64Kg—Stone= 98Kg

Mass/Cubic Meter—Cement= 520Kg—Sand= 650Kg—Stone= 1020Kg

These are based on certain assumptions such as the cement type is class 32,5. If you use a cement that is class 42,5 and higher it will give you a stronger concrete but will be less economical. The sand and stone is also given with an average moisture content. Please be cautious as to what you are using the concrete for and for structural uses it would be best to consult a professional.

what will be the outcome strength of 1:3 mix?? in PSI

What do you mean 1:3 mix? Are you asking about a mortar mix or a concrete mix that needs a stone component? It also depends on the class of cement that you are using.

what is the implication of concrete mix of ratio 1:4:6 of elephant cement : wet(river Sand): Rice (granite) in a suspended beam& reinforced floors.

Hi Koko,

That mix sounds dangerously weak for a suspended beam and reinforced floor. I would contact PPC (the elephant cement people) or a qualified engineer to give you some advice before you have a major disaster on your hands.

1., , how can take the ratio preparations if any concrete mix(m20, m250,…etc) ? 2; SRC concrete ratio will be i need?

Rajesh,

I’m sorry but I have NO IDEA what your question is. Please repost a question with some detail about what you want to know.

What mix ratio(in kg) can be used to get a concrete strength of 20mpa, 30mpa,and 40mpa minimum.

Hi Asuquo,

I have put up a page with ratios for 10MPa to 40MPa by weight and by volume here: concrete-mixes-by-weight-&-volume. I hope this helps.

If I use 5cubs of crusher run with cement must or can I use and wich mpa strenght

Hi Sydney,

This sort of technical question I think should be answered by one of the experts. So I suggest you contact the Cement and Concrete Institute on 011 315 0300 or go to the website http://www.cnci.org.za. The other experts are PPC and you can find their contact details here: ppc.co.za/pages/contact_details

You are not specifying the types of cement on mixing ratios for different applications. Is it not necessary to consider type of cement?

Hi Osward,

You are correct but what we say in the article that these are “basic” guidelines. On the page concrete-mixes-by-weight there is a “NOTE” that says:

“These proportions are based on the assumption that a CEM type cement of strength class 32,5 will be used. Cement of strength class 42,5 or higher will give a stronger concrete but may be less economical. Cements with high extender contents (eg CEM 11/B or CEM 11) will develop strength more slowly and will require particular care with curing. Masonry cements complying with SABS ENV 413-1 should only be used with specialist advice.”

Having said that I will extract specifications out of my files and post an article on the classes of cement. Please check back later and look under “Concrete Mixes”

for concrete mix ratio

for m-15 – 1:3:6

for m=20 – 1:2:4

for m-25 -1:1.5:3

for m-30 -1:1:2

can you know the compressive strength of a given concrete mix ratio (e.g. 1:1.5:3), what are the needed data for Cement, Sand & Gravel for us to know the compresive strength??? thanks

I don’t see any mention regarding the water quantity needed: Is it merely a case of ensuring it is “runny” for warehouse floors? Mpa30 recommended mix.

please i want to know the specific difference between the slump test and the flow test in concrete mixes.

From the table above, one bag of cement plus 0.75m3 of sand and 0.75m3 of stone makes 1m3 of concrete? The sand and stone alone total to 1.5m3, plus the cement must be close on 1.7 m3 ignoring the water?

Hi Steve,

Yes it does seem confusing. The measurements are correct on average, the reason for the loss of volume is mainly the empty spaces between the stone that get filled with the sand and cement. The cement also fills the small gaps in the sand as well. So it would appear that the amount “shrinks” when you add the amounts together. The Cement Institute Handbook has a 15MPa mix by volume as: 1:4:4 – 1 sack cement – 130 liters sand – 130 liters stone; vielding approx 190 liters of concrete which does not add up until you take the filling of the gaps into account. I hope this solves the problem. 😀

Thank you – makes sense

hi, may I know the correct mixed ratio for concrete grade “7”

It sounds to me as if you are a student? If so you really should be doing your own research and not asking other people to do it for you! However, the slump test is a measure of the consistence of fresh concrete – and it is the distance through which the top of the concrete moves down during the standard slump test according to SANS specifications. The flow test is only suitable for highly workable concrete that has a slump that is greater than 150 mm. It is also done according to SANS specs, using similar equipment to that used for slump tests. The flow test gives an accurate measurement of the workability of the concrete and an indication of its cohesiveness.

Lameck I am not sure. Here is a link to a table that gives proportions for Grade 7 concrete – but I cannot guarantee its accuracy. Hope it helps.

Brian one generally adds just enough water to ensure a pliable mix with good consistence. It depends largely on the size of the crushed stone used, but if 19 mm is used (which is common), plus an average quality sand, and a CEM 1-type cement (a common rather than masonry cement) – no admixture and measured to a slump of 75 mm then you will need on average, 210 litres per cubic metre of concrete. Ref: Fundamentals of Concrete by Brian Addis

Melvin there are examples on this page. BTW in SA we normally use crushed stone rather than gravel. Also when you use the kind of ratio you are quoting this is based on mixing by volume – i.e. using the same sized container for each dry material – and it is only suitable for small projects. If using a builder’s wheelbarrow, you can assume that two sacks of cement (50 kg x 2) = one wheelbarrow load of either sand or stone. Low strength concrete could be mixed in the ratio of 1:4:4 and would be 10-15 MPa at 28 days. Medium strength might be 1:3.5:3.5 = about 25 MPa. High strength 1:2:3 = no more than 40 MPa. But it really isn’t a reliable method and shouldn’t be used for major construction e.g. a house.

I thought I had my foundation mix clear in my mind (house extension) but now my supplier has suggested pre-mixed sand and stone – they claim it is a 50 /50 mix by volume. This is great as it saves much-needed storage space but the question begs – how much cement /m3 of the mixed sand/stone for a 15Mpa mix?

I learnt on this page that ,75m3 of each + 5.5 bags of cement (plus water) only makes 1m3 of concrete, so it is obviously not a simple matter.

Thank you

Hi Steve,

I agree it looks confusing, if you have a look at the first illustration on his page it says below the wheelbarrows that for 1 cubic meter of 15Mpa concrete mix .75 cubic meters sand and .75 cubic meters stone with 5 1/2 bags cement. So for your premix you must take into account the volume shrinkage when the sand fills the cavities between the stone. So .75 plus .75 will not end up as 1.5 cubic meters of mix but closer to 1 cubic meter then you must add your cement which will further fill the smaller cavities between the sand and stone. The shrinkage will be greater with a bigger stone size and coarser sand as well. Water is not taken into account as this will evaporate and the mix will shrink to its final volume. The Cement and Concrete Institute do say under “Estimating shrinkage. Because of the number and complexity of factors , estimating is, at best imperfect.” So with this in mind rather add a bit more cement to the mix and make it stronger rather than weaker.

hi , I am a little confuse , in relation of mixing of concrete , I need a 4500psi strength , what are the mix I should used

Hi Nanda,

I am also a little confused, because concrete strength is measured in Mpa (after 28 days). Have a look at the table on this page that gives the range mostly used in ordinary construction today: concrete-mixes-by-weight If you have a unique structure that requires a special concrete mix then you will have to consult a structural engineer who will draw up the specifications for you.

hye.may i know the correct cement ratio with strength 30Mpa at 28 days? please help me.

Hi Sakinah, I have added a table at the end of this story with concrete mix proportions in ratios. I hope this helps.

Good day. I’m a Quantity Surveying student who would like the estimated:

1) cement, sand, stone and water quantities for a 5000l trial mix of 30MPa concrete, with cement type CEM 1 42.5; and

2) cement, sand and water quantities for a 1l grout mixture to be used in CFA piles

I forgot: I look forward to hearing from you. Thank you for your gracious time.

Hi Lungelo, as much as we would like to help you it sounds like this is an assignment, and it is our policy not to do homework for students. You will have to do the calculations yourself. Good luck with your studies 😀

Hi, building a double storey house my ground floor is 210 sqm was advice to use 25mpa spec needed 19mm 70:30 mix 42.5mpa all in is 35cu just need to know how many ton (single truck) will a use and my first floor is 183sqm all in 36cu, please help just need to know how many trunks will i use?

which contractor that can build us concrete house with its required insulation

Nathi, unfortunately we cannot make recommendations. Make sure whoever you approach is registered with the NHBRC.

Your best bet is to contact a ready-mix concrete company and ask them to do the estimates for you. They will be able to give you a pretty instant reply.

Hi there,

We are preparing to extend a house and according to the quotation, I was suppose to building sand 10 cubic meter and at cashbuild they gave me 1 cubic meter sand. What is the difference?

What is the good ratio for making quality bricks (Sand and Cement only) using Afrisam and how much water is needed in that particular ratio?

Hi Bernard, I have uploaded a file for you to download on our downloads page, just scroll down to “Concreting & Blockmaking”. This an AfriSam brochure that gives you all you need to know for your project. Basically they say that as a rough guide, using an aggregate cement ratio of 8:1 by loose volumes, three and a half bags of cement and a cubic metre of aggregate will be enough to make about 400 standard bricks. There are other factors that they talk about and you should read the whole paper first before starting. Good luck!

Hi Dumisani, If you look at the amount of sand delivered then times that by 10 then that will be what 10 cubic meters will be. BTW 10 cubic meters is a lot of sand.

Hi

I need an hand book Article or any Text book that will Educate me on different concrete mixes and morta mixes.

I need to learn more to be able to implement better

Hi David, go to our downloads page (ownerbuilding.co.za/free-downloads) there are a number of leaflets that will help you. You can also go to our other site for more info: buildingregulations.co.za

I want to know about water quantity with the mix ratio for 25 mpa strength

Please have a look at our post for mixes here: concrete-mixes-by-weight There are no hard and fast rules for water quantities most builders do it by eye and feel so long as it is not too dry or too wet. The professionals and readymix suppliers will do slump tests on batches to assess the correct mixture for specific applications and will depend on the materials used and the consistency required.

Hi, how many bags of cement, stones tonnes and sand tonnes do i need to do a slab of 50 cubic meters.

Regards

Kelvin

We have a table for weights and volume for sand, stone and cement so you can easily work it out here: concrete-mixes-by-weight

1 m3 contrete (manual) mixing howmany bags (50 kgs) cement

MT Sand

cft 20 mm metal required

Can any one assist me to know the proportion for 20MPA Concrete Design Mix

If you go to this page: concrete-mixes-by-weight there are tables with the various Mpa so you can easily work out the proportions.

Hi,

What proportion of cement, crush sand, fibres and chemical will be required to make a concrete mix design of M60 grade?

Hi. I am building a diy pizza oven.

I want to build a small rectangular slab which will be suspended, but supported on all 4 sides. The slab total size is 1200 x 1200. I want to sit the slab on top of blocks on all 4 sides. The overlap will be approx 170mm on each side.

This is to be the cooking floor of the oven. I need to know what ratio is best and how thick the slab should be. I have mesh to put inside the slab as extra support.

i purchased bags of concrete mix from the local hardware store. When I opened the bag, the ratio of cement looks very low to the sand. I have since bought seperate bags of sand and grey stone. I will need to purchase more cement.

The medium/strong ratio as above looks good. But how much of each will I need for the slab size needed?

The pockets of stone and sand come in 40kg bags. Not sure of the cement.

thanks

For what you are wanting to do and to make it a safe structure I would advise asking a structural engineer to assist you, if the structure were to collapse and someone was hurt then you would be liable and you would have no insurance cover either.

I want to throw a white cement and fine crusher mix on a bathroom floor, which I want to polish. What mix do I need

Hi John, the best would be to call the experts in this field, Cemcrete. Their contact number is in our post: decorative-concrete-floors

Hi

We want to make our own concrete kitchen countertops, but are battling to find info on the ratio of the mix we should use for this.

Websites from other countries indicate that one can buy special cement for this purpose. Is this available in SA as well.

Also do you have any advise on the best stain to use for this kind of project.

Hi Karen, we have put together an affordable “Concrete & Mortar Handbook” that might answer your questions please have a look here howtobooks.co.za/product/concrete-mortar-handbook/

Hi Raj, we have put together an affordable “Concrete & Mortar Handbook” that might answer your questions please have a look here howtobooks.co.za/product/concrete-mortar-handbook/

How do I measure how much concrete mix is needed to lay are 300mm thick foundation 15m long

How much concrete mix and how many bags cement

Hi Julian, read here: http://sans10400.co.za/concrete-mixes-by-weight/ or buy my E-Book here: http://www.howtobooks.co.za/product/concrete-mortar-handbook/ for only R59

Julian you also need to know how wide the foundation is. You then multiply the length by the width and then by the depth/thickness and get your cubic meters then work out the quantities you need for that many cubic meters.

Hi how do i download this e book do i need a lot of data and how do i pay the money in thanks karl

Hi Karl, I have just checked the links from the books and they are all working fine. For the Concrete and Mortar Handbook and the Energy Efficient EBooks you will be directed to my book site howtobooks.co.za with a secure PayFast payment gateway. The Owner Building book is sold for me by Loot. Thanks for the support. Janek

hello i want to find quantities per cube for each strength of the following materials cement, stone, sand, water. i would like to see the steps in calculating it. Please help i so stuck i feel like my head is about to explode.

Hi Gugu, It is all explained in this E-booklet: Concrete-mortar-handbook

Hi there, is this book available in stores, beside online? If it does where can buy it?

Hi.my head is very quick and intelligent in the construction field but I always find my self sidelined due to luck of funds for studies.am not sure if have any advise for me.thanks.

hello,I am a new student in civil engineering field and I want you to reply me my question’s answer.

1.what are the mix ratio that can be use for this following concrete:slab,bathroom floors,kitchen floors,car pack,garden,masonry concrete slab,columns,foundations.

2.is it necessary that the mix ratio for columns should be different from the one for the foundation.

Sorry Dawud, we don’t answer assignment questions for students.

Persevere.

really interesting topics for CE. missed this site from a long. keep the good works going on.

Hi

Is there a huge difference financially between ready mix and “self mix”. I received a quote for ready mix 25mpa @R1444.00 per m3

Hi Leticia, With self mix you must calculate the cost of sand:stone:cement:water as well as the cost of hiring a concrete mixing machine for the time it will take to mix the quantity that you need for your build. Then you must calculate the cost of your labour to get your required amount of concrete where you need it. The m3 costs will vary from city to city and town to town in SA.

Thank you. Ready mix sounds more convenient.

Very very educative. Thanks a million.

thanks for the lecture, I love it

It all depends in the area you are situated like durban price is not the same as Richards bay.The distance between where you want concrete and the batching plant is a big factor when pricing

Hi Janek

I am in Pinetown (KZN) and i would like to find out if you know any store where i can get your book?

Hello. Let’s say I order 6m3 of ready mix concrete, how do I check, in the truck, if the quantity of concrete is what I ordered?

Good day

I’m having my foundation lifted on the side of my house and under pinned. I’ve been told to order different quantities from quote to quote regarding the mix ratio. One is what I see here 50/50 mix medium strength. The other is a 1:2:3 cement, sand, stone. Is the later weaker, and should i reject the quote or is it still acceptible?

Hi, I can’t make complete sense of the difference of mixing ratios between’ Large Batches of Concrete Mixes’ ( 25 Mpa =7 bags cement(0.231m3) , 0.7 m3 sand , 0.7 m3 stone gives a ratio of 1: 3: 3) and ‘Small Batches of Concrete Mixes’ which states that the 25 Mpa ratio is 1: 2.5: 2.5) that almost 17 % less sand & stone ?

how do you control the amount of water for the above mix, 15mpa, 25mpa & 30mpa ?

When you mix concrete you add water gradually until it has the right consistency. It shouldn’t be runny, but must be pliable enough to work with.

Hi Glynn, You can’t just convert quantities for small batches to a ratio and then compare the ratios to large batches. Mostly small batches will use a smaller stone and will be hand mixed and large batches will be mixed using a larger stone and a concrete mixer or delivered by a concrete pre-mix company. This is a confusing thing with concrete and mostly this is to do with the size stone being used, commonly 19mm, 13.2mm or 9.5mm. The larger the stone the more empty volume/space between the stones that has to be filled with sand and cement and conversly the smaller the stone size then, by proportion, there will be less sand and stone. This will also vary with the concrete strength High (30 Mpa), Medium (25 Mpa) or Low (15 Mpa).

You tell me! Use a reputable company that won’t rip you off.

Which book Pule? Our only printed book that is still in print is Owner Building in South Africa and that is available at all good bookshops including Exclusive Books. Our ebooks are available from howtobooks.co.za

The trucks normally take only 6m3 so if you look in the truck should be full, bear in mind a little space for the mixing so its not overflowing. I’d say about 85% full. Also calculate the place where you pour the concrete if its filled up if you worked it out to be 6m3.

I find this guide very problematical and thus misleading and therefore dangerous as follows:

1. Your pictures clearly show the ratio of sand, stone and cement THEY are so clear that it is more than likely that the ratios in the pictures will be used without consulting the ‘fine’ print.

2. The fine print says that these ratios are for wet sand therefore your pictures should also say wet sand!

3. You also need to say that the maximum water content of the mix, including the water in the sand is xxx litres, on each picture.

You really need to correct this.

It would be really good.

Hi Ross, Thanks for the comment. The water part of mixing concrete is NOT an exact sience I’m afraid to say. It is impossible to say how much water is in a damp sand that gets delivered to any one site. We do say “You will also need to add more water to compensate for the lack of water in the sand.”, so the saying “The mixture must be not too dry and not too wet” applies.

Hi Ally, Sorry for the delay, we do the replies on a voluntary basis when we can. This can only be answered by a “competent person” who should be overseeing the build and will specify the ratios needed for your soil conditions etc. This should have been specified when plans were submitted to council.

Slump tests also determines if the amount of water added is ok, it is used to determine the consistence of the concrete mix.

Hi

I have to design a high strength mix of 60 Mpa for a school project and im almost clueless on where to start. All we have been instructed is to use 42.5 N Cement. Has anybody designed something similar and what material were used to achieve the high strength?

in my mind im already thinking something Fly ash would be necessary to help increase strength but at the same time help mitigate the low water cement ratio necessary to achieve high strength. Crushed limestone with aggregate size > 8 mm.

Am I on the right track, any help would be appreciated.

Fly ash is used as an inexpensive cement extender – it is used by cement manufacturers. It is not going to increase the strength of your concrete – in fact it will reduce the strength though it will improve workability. You might add FA to your concrete if the concrete was going to be placed in an “aggressive” environment.

The materials you will use are cement, sand and crushed stone (available sizes 9.5 mm, 13,2 mm, 19,5 mm or 26,5 mm). I do have tables for trial concrete mixes but they only go up to 40 MPa. According to Fulton’s Concrete Technology published by the CCI, which has a chapter on concrete mix design (maybe there’s a copy in your school library?), high-performance concrete with a 28-day compressive strength of 68,9 MPa = high strength concrete. The chapter on high-performance concrete says that the best cements to use for (high-performance concrete) “for South African conditions,” are CEM1 42,5R, 52,5N, 52,5R. From a table in another chapter, I see that the early compressive strength (MPa) of 42,5N at two days is about 10 MPa and 42,R about 20 MPa. Both reach between 42,5 and 62,5 after 28 days.

In the chapter on high-performance concrete, it states that substituting about 8% of the cement with condensed silica fume “could enhance strength”.

It also says that tests done with South African aggregates have shown that the “optimum nominal size for coarse aggregate” i.e. crushed stone – is 19-26.5 mm.

As far as sand is concerned, “a fineness modulus of 2,7 to 3,0 should be suitable.” Crusher sand is preferred in SA.

It also states that a “good quality superplasticizer is an essential ingredient of high-strength concrete.” It explains how to work out the quantity required – tests need to be done in a lab.

NB In this chapter it is also stated that “there is little experience in South Africa of the manufacture of high-strength concrete.”

So they have given you a very difficult task.

Maybe these trial concrete mix quantities might help:

MPa at 28 days Cement Sand Stone (19 or 26,5 mm)

10 50 kg 230 kg 196 kg

20 50 kg 130 kg 164 kg

30 50 kg 90 kg 114 kg

40 50 kg 64 kg 98 kg

Notice how much less sand and stone you need the higher the MPa needs to be.

Your water/cement ratio is critical.Any high strength concrete design should include the “slump” allowance. This is the amount that concrete placed in a cylinder will sag or slump when the cylinder is removed. A layman should not be thinking of designing 60 MPa concrete without the advice of a civil engineer or the Cement & Concrete Institute who are always most helpful in my experience (011) 315 0300.

You can get the book here: http://www.howtobooks.co.za/product/concrete-mortar-handbook/

How do I find the mix ratio of masonry foundation

Hi Claudy, Any foundation must be designed to take the weight of whatever it is going to support. This goes to depth, width and MPa (the strength of concrete for the specific job) and if additional reinforcing bars need to be included. Read here about concrete mixes: http://sans10400.co.za/concrete-mixes/